Towards the end of 2019, as we were wrapping up our final semester, the COVID-19 pandemic unfolded, disrupting everything. Events like the RoboCup competition were canceled, and universities went online. Our robotics lab, once buzzing with activity, fell silent.

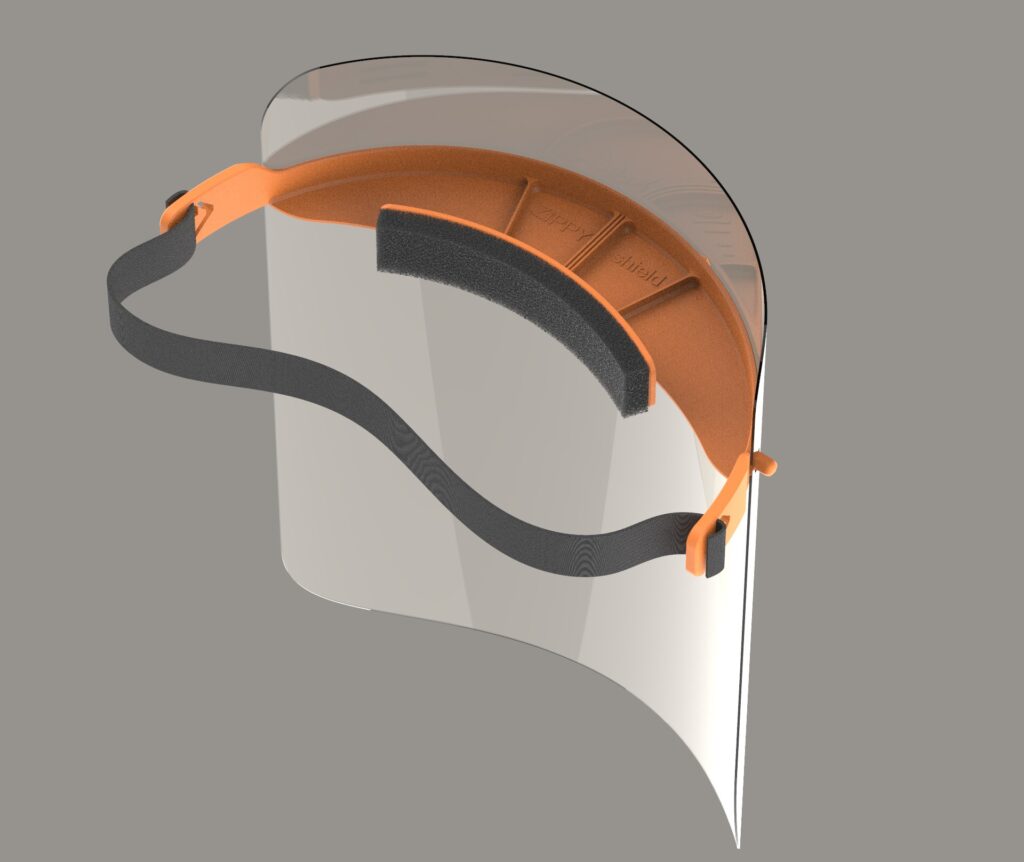

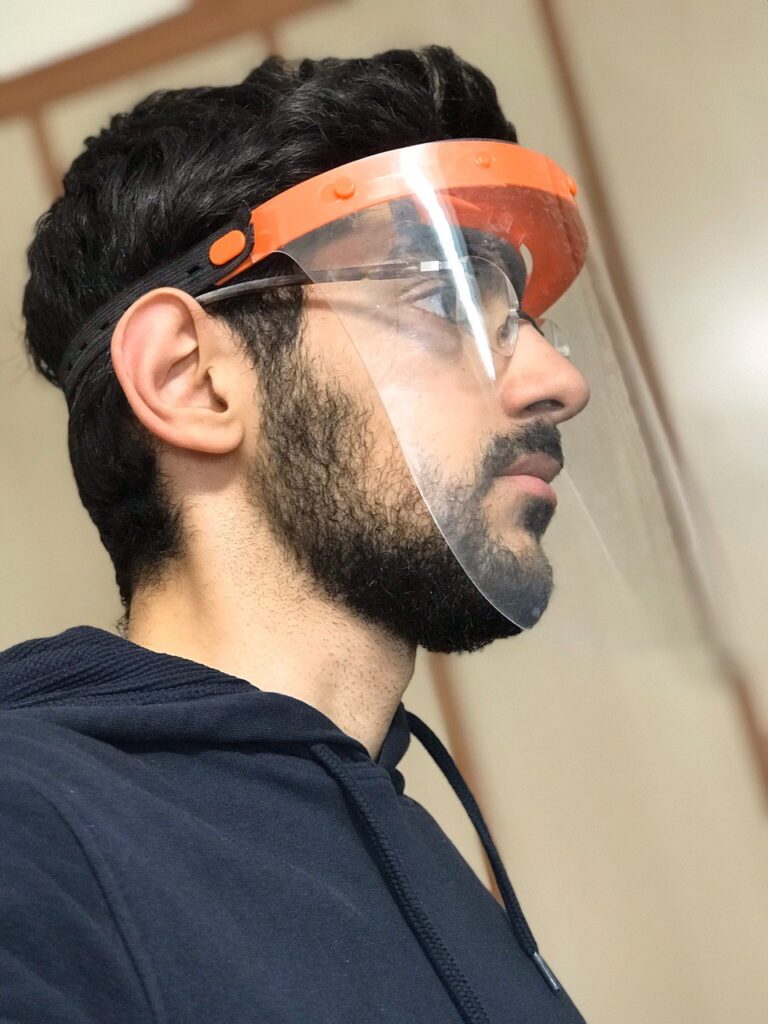

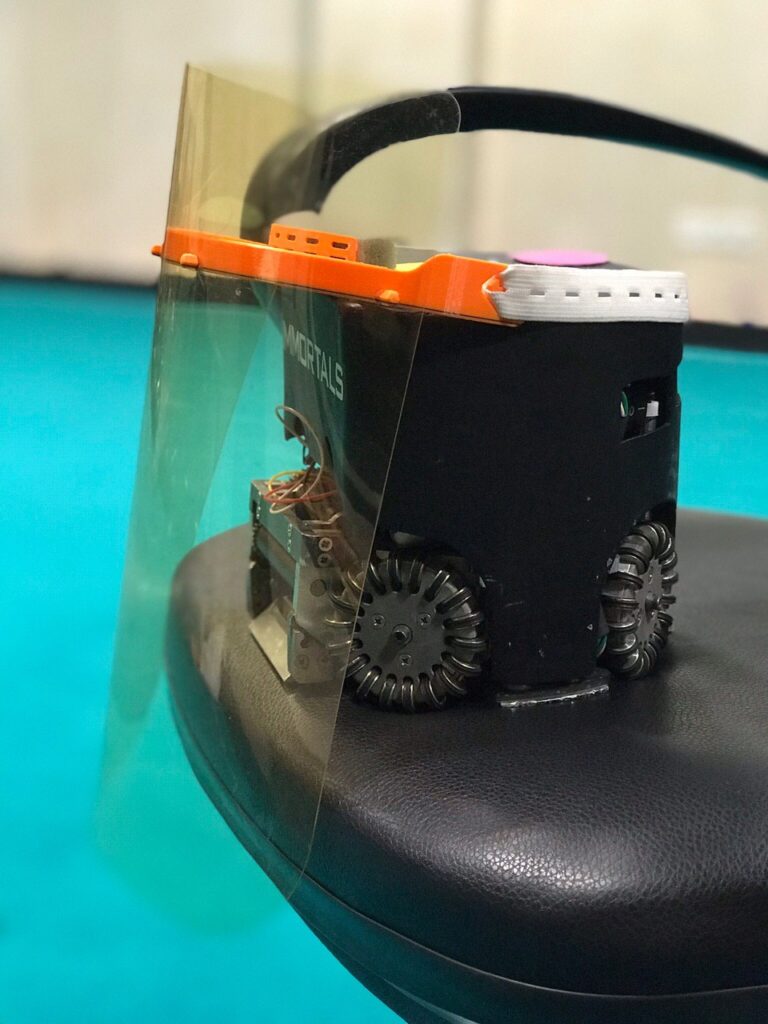

After a few months, the news highlighted the urgent need for medical supplies. With the pandemic persisting, our team wanted to help. We realized we could use our 3D printers to make face shields. Thanks to our friend M.A. Ghasemieh, we designed a simple face shield holder using CAD software.

This holder, made to secure a transparent sheet, turned into a practical face shield. It was a small but helpful solution, using our 3D printers for a cause beyond robotics. We actively joined the fight against COVID-19.

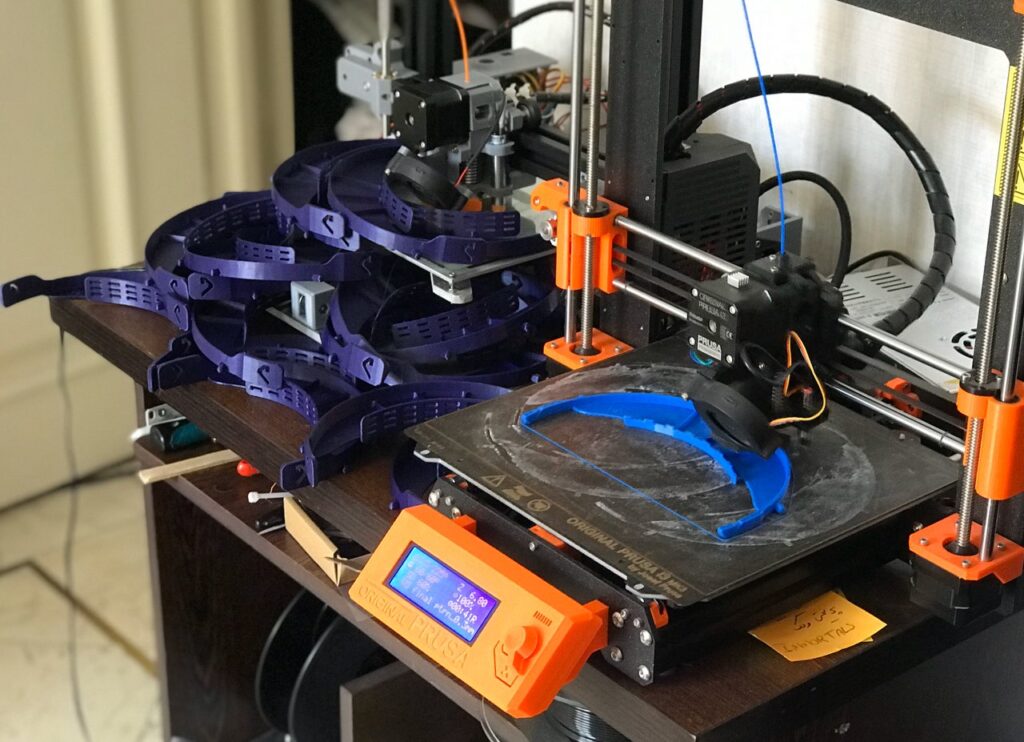

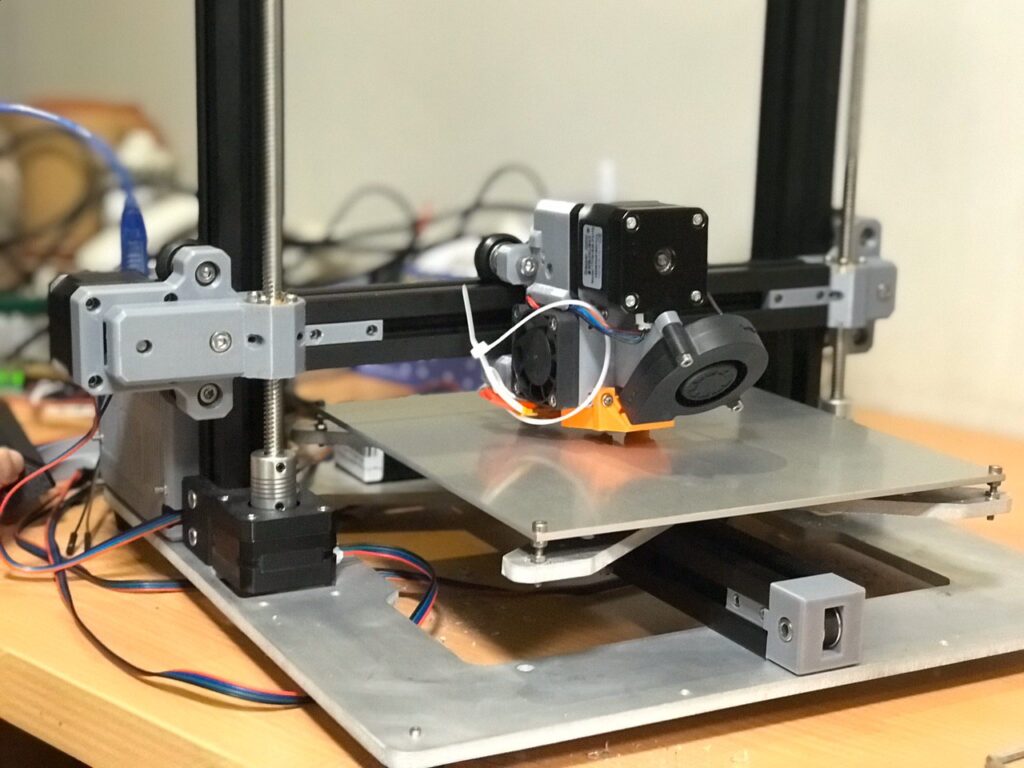

As the final designs took shape, our 3D printers worked non-stop, shifting from making robot parts to life-saving equipment. This unexpected turn not only showcased our adaptability but also highlighted the power of using our skills for a greater purpose.

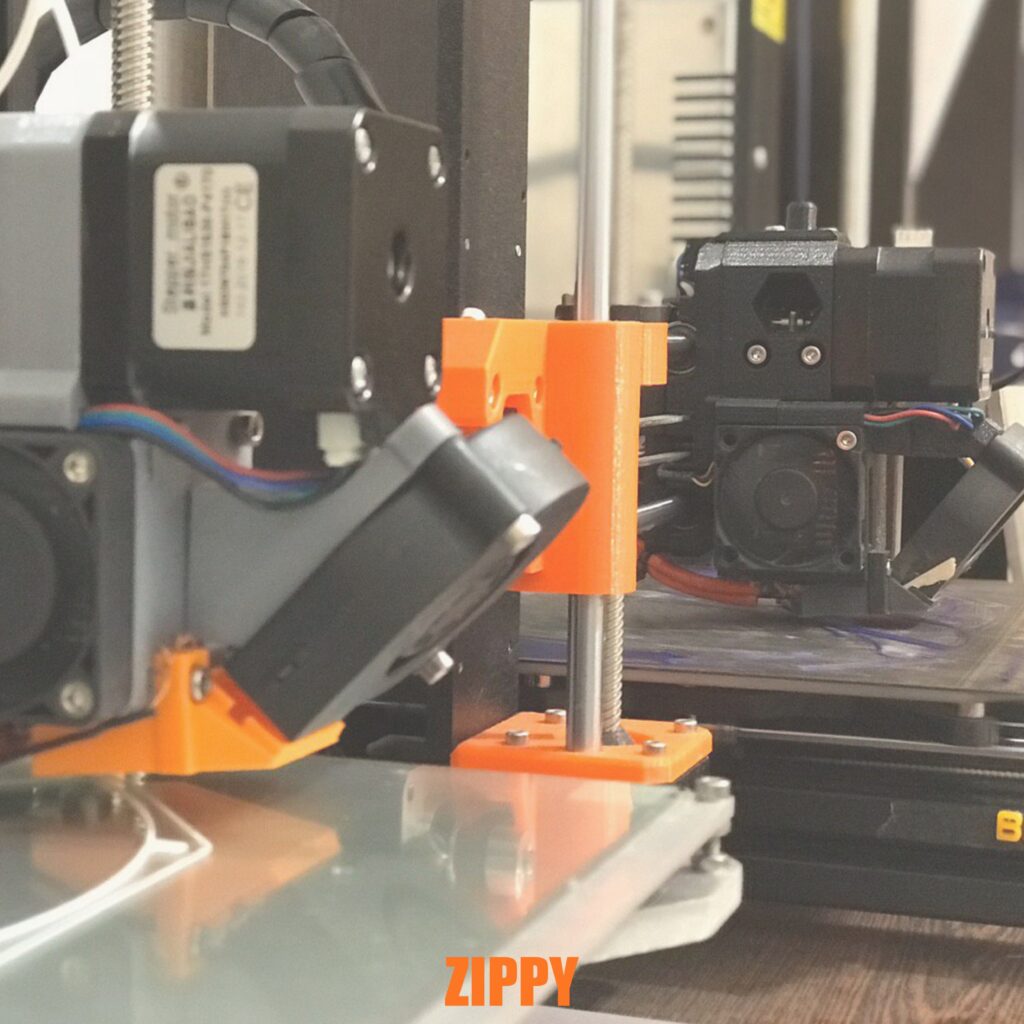

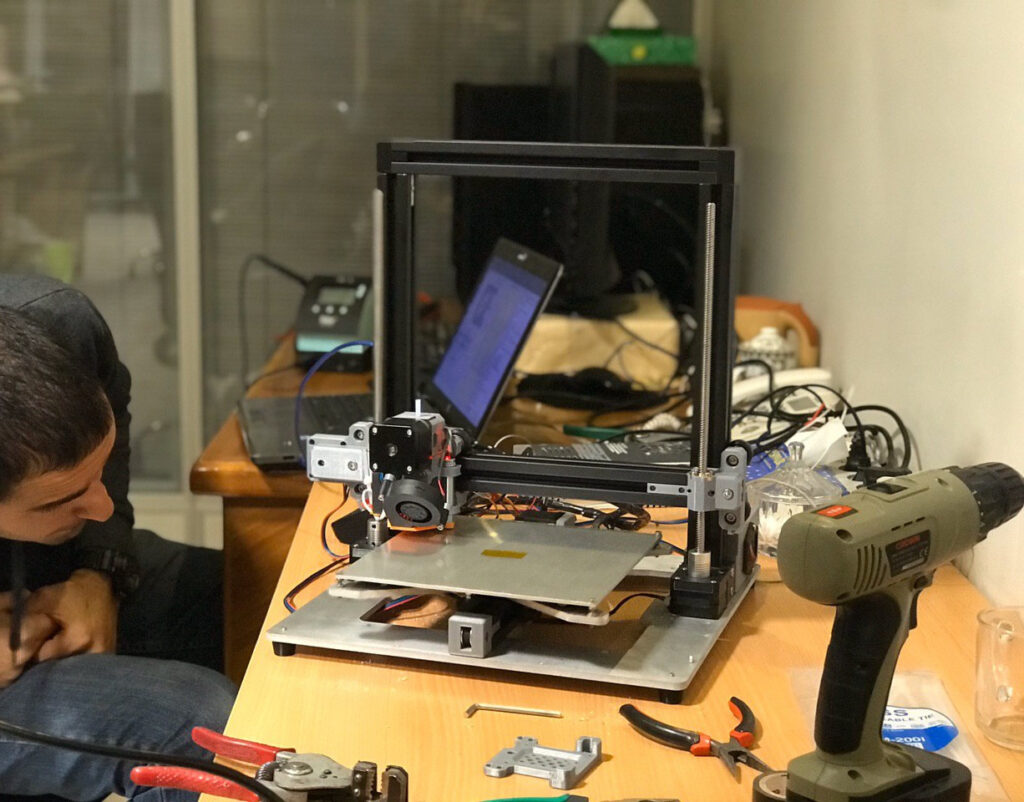

During that time, I took on the task of constructing a new 3D printer using available resources to enhance our production speed. This endeavor involved dedicated work, leveraging open-source projects like Marlin. Eventually, I successfully built our first 3D printer from scratch.

Following that, we accelerated our production to almost 10 shields per hour. As the demand for our face shields increased, we opted for a faster production process. Consequently, we transitioned from additive manufacturing to plastic injection manufacturing.

It quickly became evident that the new production method was significantly faster than our previous approach to building shields. We achieved a production rate of more than 100 shields per hour with minimal failures, a notable improvement over the common issues encountered in additive manufacturing. Below, you can view the results of our final products, which we named the Zippy Shield.

At the end we managed to produce around 20,000 masks. Most of them were dedicated to charities and the rest were sold to cover the expenses of the production line.