In 2020 Me and my teammates from Immortals Robotics were offered a project to build a 3D printer. At that time we were using 3D printers to build the first 3D printed soccer playing robot in the RoboCup Small Size League.

The project was to build a 3D printed clay machine for a small business in the field Handicrafts. The client was experienced in building all types of products made out of clay but had never been in such a project which required a great amount of engineering knowledge.

At first, my teammates who were in charge of our robotics mechanics, managed to design and build the mechanics of the clay 3D printer. Then with their help we processed the electronic needs and Implemented the needed circuits to control the motors of this heavy structure.

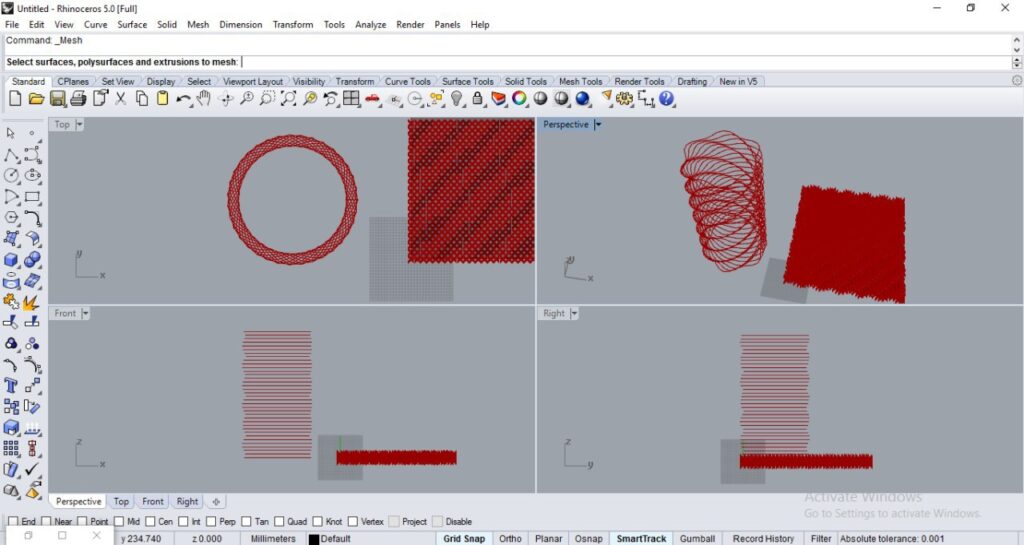

I was in charge of handling the circuits and the software needed to be deployed on the machine. At first I wrote the firmware which was a modification of the Marlin open source project. Then I wrote a simple script to generate a g-code file which is a file which contains simple commands for a 3D printer to tell what it should do in order to build an object. For example move straight to this point in a 3D space while extruding X amount of material outside of your nozzle. The g-code generator was first made in a 3D designing software called Rihno along with a plugin called grasshopper.

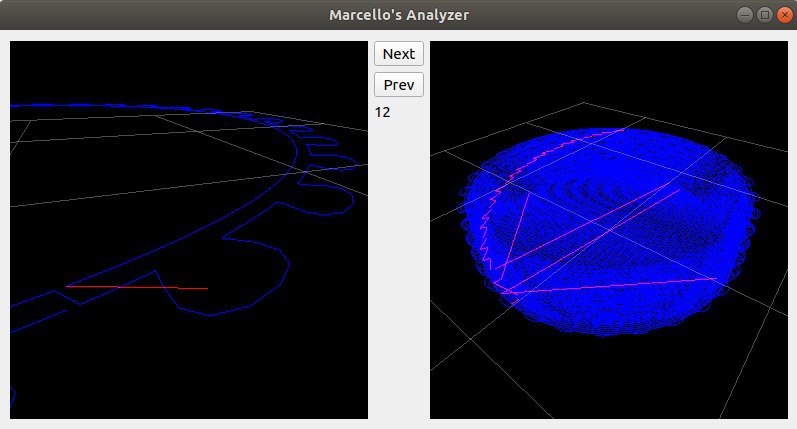

Due to the heavy processing of the software I decided to design my own software with python using graphical libraries such as pyqtgraph and other libraries for computation such as numpy. Below is a snapshot of it’s interface:

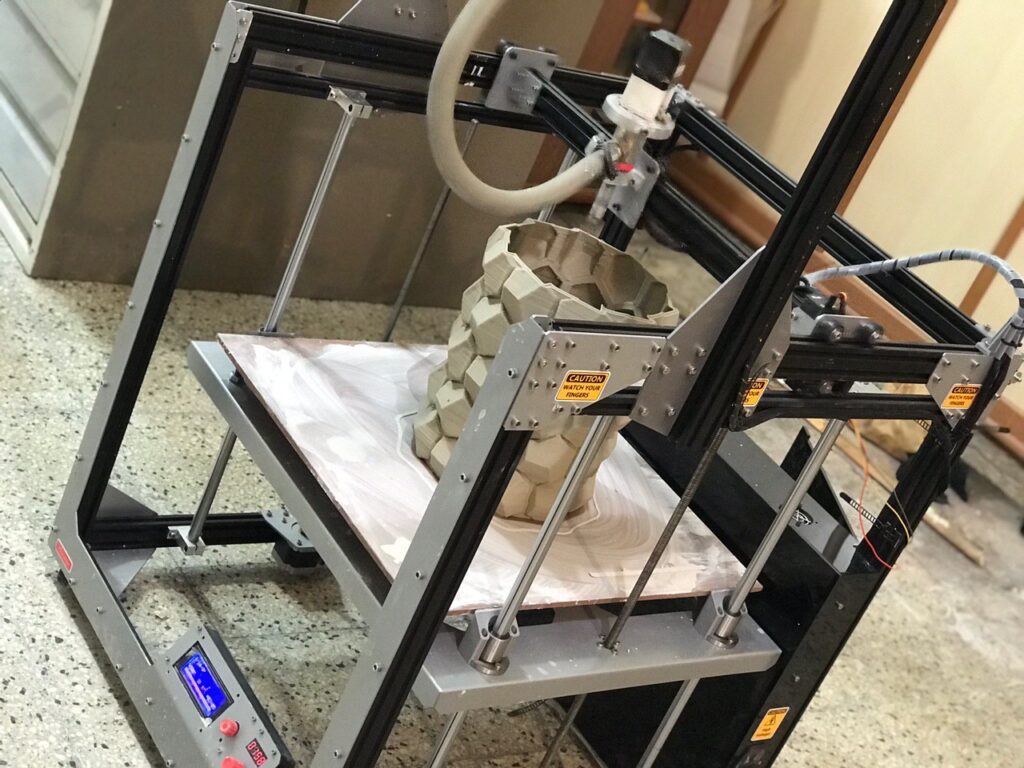

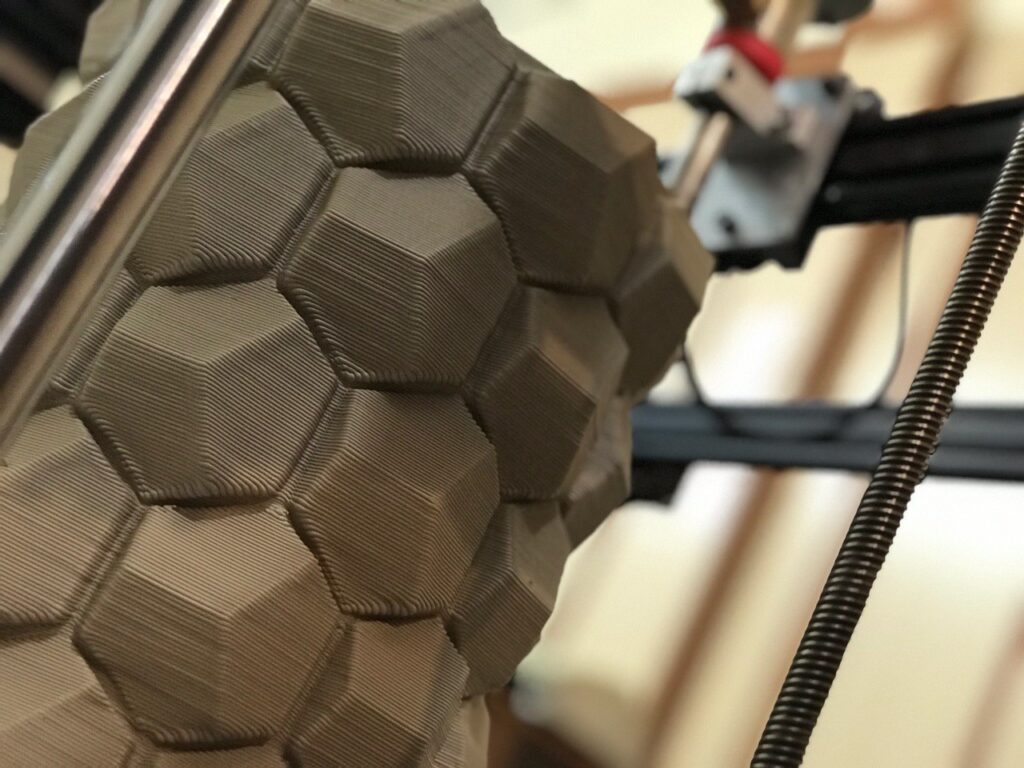

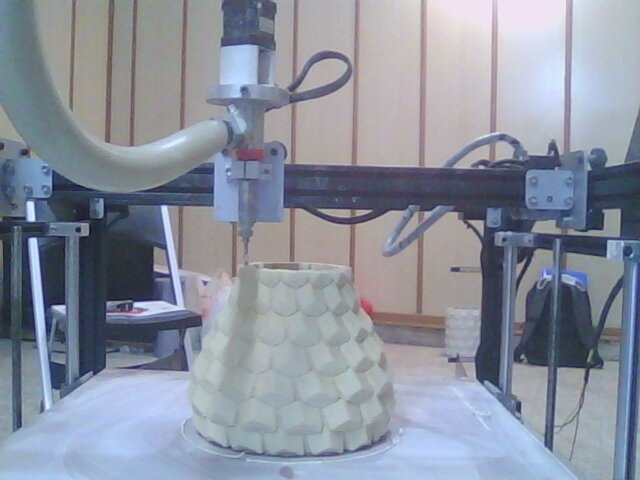

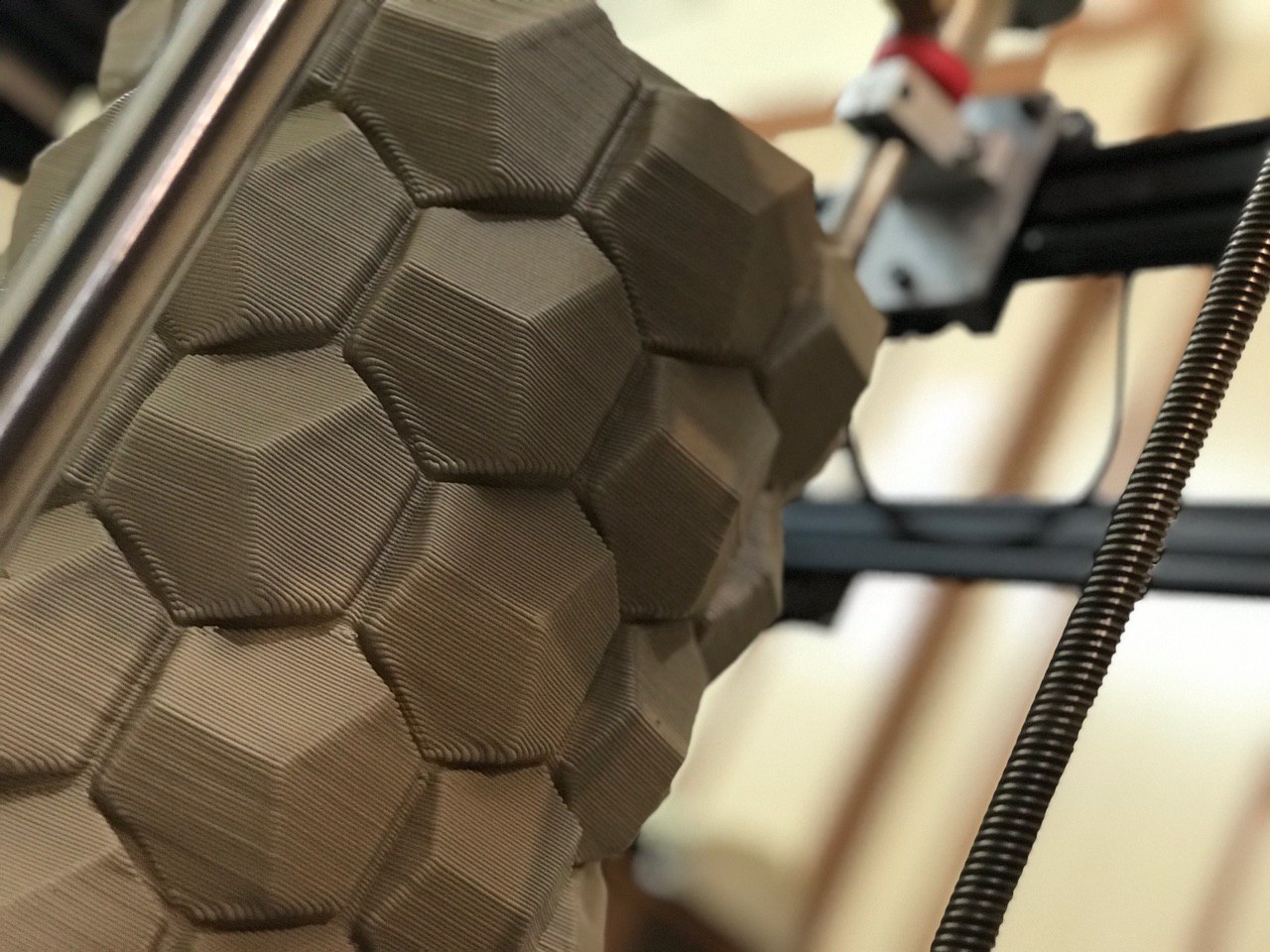

After about 6-months we finally made the achievement and finished the project. Below you can see the final result of our work:

The final result of the 3d Printer producing a clay object is as below: